Satellite tracking antenna • HAM radio • ISS • Visual observing • Tracking software • Iridium flares • Satellite tracking system

Satellite

tracking

(BB_TRACKER

V4.6

21_March_2013)

LOW

COST

DRIVER

&

HARDWARE

FOR

THE ORBITRON

PROGRAM COMMAND

TWO

TV

ROTORS

IN A

PORTABLE

SATELLITE

TRACKING

SYSTEM IDEAL FOR FIELD DAY.

Aqui

em Portugês

INDEX

-

How

to install

the driver on the

Orbitron

and Dowload

the

Driver

-

KIT and

printed

circuit boards

-

Contact us

for

more

information

-

PHOTO GALLERY to understand the idea

Field day prototype test

http://db.tt/TOF7BLpN

(Thanks to GRC (Grupo Radioamadores Cascais)

INTRODUCTION

The

intention to enter

the world of

satellites and

space at low

cost, led us

to develop a

driver

for the program

Orbitron

able to command

two

rotors

of

moderate price,

thus, making

a system for

the

following

of

Satellites,

Moon, Sun etc.

The

complete system of

components

hardware

are

purchased from the

market

and

should

not exceed €

400.00.

With

the use

of reasonable

gain

antenna,

the system

optimizes the

contacts from

horizon to

horizon

and frees your hands.

The system

consists of

a

software

driver

that can

be downloaded

on the

link page

above.

This

Driver

extracts

every moment

the

Azimuth

and Elevation

of the satellite

selected in

Orbitron

and sends

them to

a

micro-controller

board

that will

control

the

rotor-controllers

through a

system

of

LEDs

indicators

PCBs

installed

over the

rotor-controllers.

We are

preparing a

manual

that explains

how to

assemble all the kit,

install

it

and

operate.

In the

following

lines we describe the

development of the

idea

for a Mule prototype being

that,

in the

end,

we will have

a system with

3 Printed Circuit

Boards

(PCBs)

with all the

electronics so,

it just will be

needed

to

assemble

the parts

according to the

instructions manual.

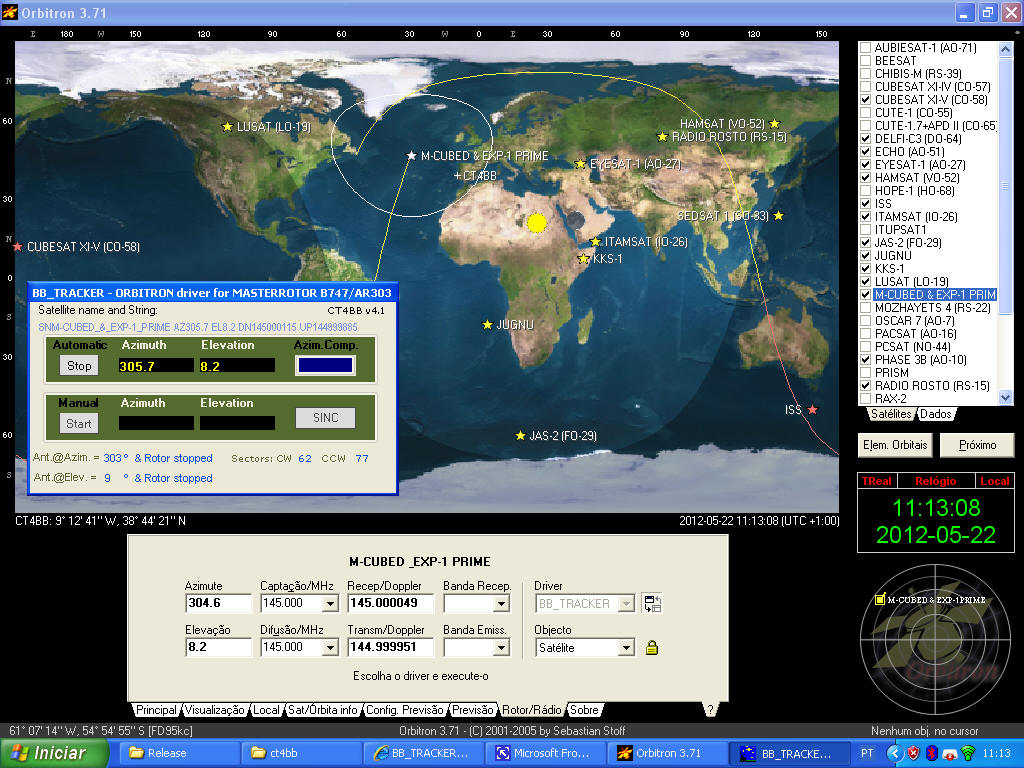

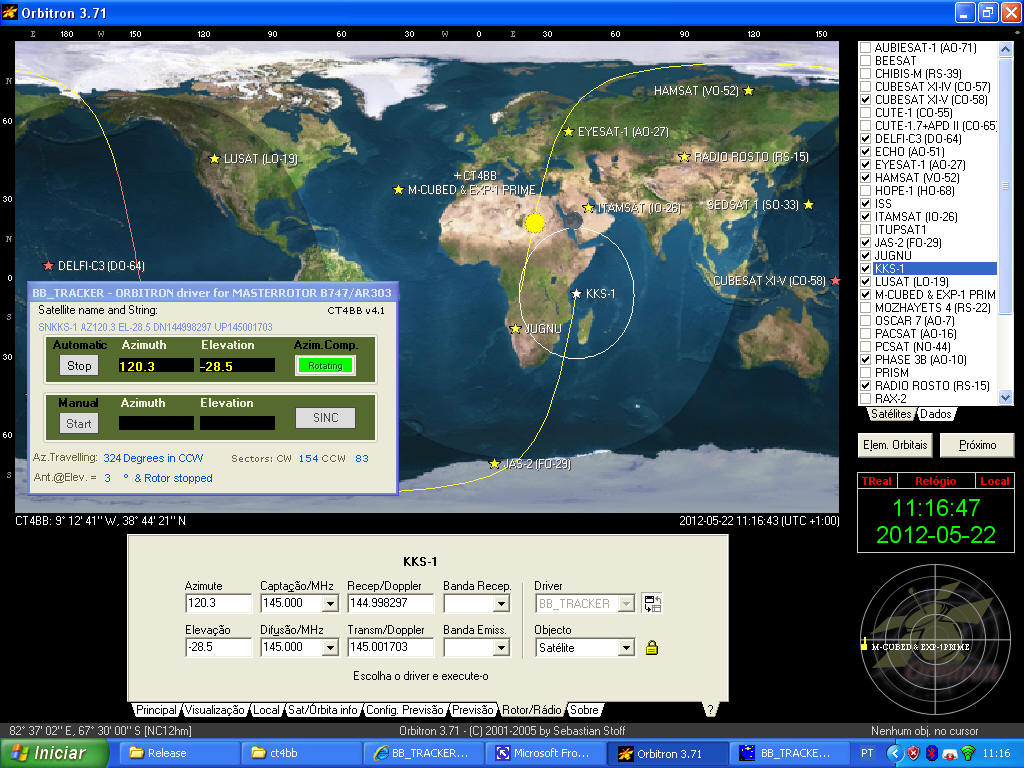

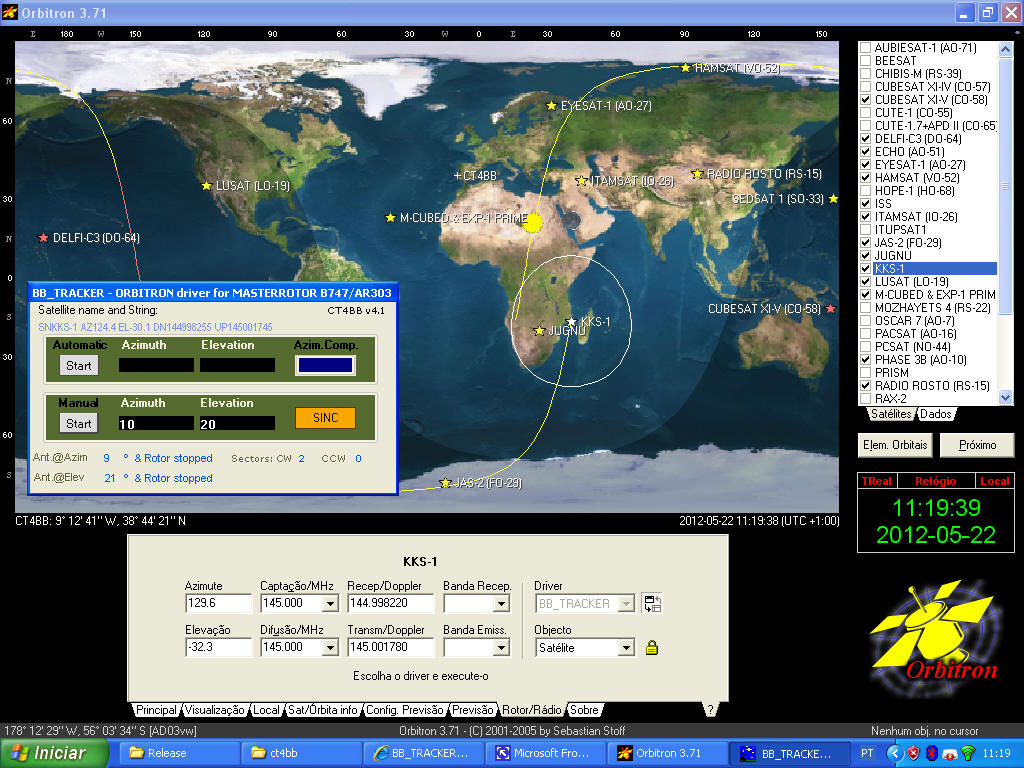

DIVER FOR THE ORBITRON

Aspect of the driver inside the ORBITRON

Before the compensation, this window previously notifies the operator that will carry out a compensation by coloring orange.

The

SINC

button is active

in

orange

color,

when

the driver is openned .

It is desirable,

before

the

passage

of

any

satellite,

to do

the compensation

and

synchronization

.

- Low cost system for satellite tracking.

- The system is a Kit that can be mounted by any ham with minimal knowledge.

- Driver works with Orbitron which is a satellite tracking program available for free downloading on the Net.

- Rotors used are type TV MASTERROTOR models B-747 or AR-303 which are well suited to the VHF and UHF antennas.

- The system has a precision of + - 3 ° that is more than sufficient for the opening angles of the antennas with 13 elements.

Costs

The total cost

of the System

wil be about

400.00

€.

- 2 rotors MASTERROTOR B747 AR303 to acquire in your local the market. (They are for € 50.00 each in Portugal.)

-

Our KIT with

3

assembled

PCBs,

and accessories

for

170,00 €

(Packaging & shipment included).

Note: you will bee

billed of VAT in your country customs

- Tripod or garden umbrella for about € 30.00. Purchase it on your local market. We got our from Leroy Merlin

- For the power supply use any 12V 2A . We used an old PC powe supply . Or get one for about ~30,00 €

- Time and patience to assemble the kit cost (€?).

Disadvantages

-

Rotors

are

low cost,

so, at

the end of

a 360

°

movement

some

+- 5º

comulative Azimuth error will happen

.

However, this

error does not

affect the

tracking of

satellites with

antennas

openings

of

+-

6º

at

-3dB

which

are

just the type of

antennas

we

use

for

VHF

and

UHF

for Amateur

Satellite

Comunications .

-

The antennas

should

be

installed

so that,

the center

of gravity

of the boom must stay

on the

elevation

rotor,

to avoid

slippage.

1 -

Use of an easy and friendly tracking

satellite program

ORBITRON

2

-

Low price

3 -

Suitable for

use in

tracking

LEO

satellites.

4 -

To modify

rotors,

it is only necessary

to

open the

azimuth

rotor

and saw

the

two

locking pins.

5

-

The system can

be synchronized

and

do not winds cables around the mast.It makes an automatic "Unrolling".

6

-

The placement

of the

Led

PCBs

is simple:

just remove

the buttons

and the contacts

of the controllers

and place there the PCBs.

7

-

The

system

allows anyone

with minimal

investment

and ability

to enter the

LEO

satellite

communications

8

- The system can

be also

be

remotly

controlled

by

entering

the

remote

PC

over the Internet..

MULE PROTOTYPE

Hardware and software

needed for

the

portable system.

-

2

ROTORS

with

Controllers(type

MASTERROTOR

B-747

or AR-303),

1TRIPOD

(Quadripod),

1 TUBE

with 1.5m

-

3

Printed

Circuit

Boards:

2

PCB/s

with position

LEDs

for

the Azimuths and elevations to mount

in

the controllers.

1

PCB Mother Board equipped with

a

microcontroller

to

place inside

the

chassis, or

box where

will

be

all

the assembly.

We have built

our prototype

on a

wooden board.

-

One

tripod

or an umbrella garden base

-

An

old

PC

power supply

can be used

where

we

take the

12

volt

~

2

A

minimum.

-

5

Flat Cables

with

16-conductor

with

2 x

ICD16

female

connectors

to connect the

microcontroller

PCB and

the

Led

position

PCBs.

-

2

x

10

meters

of cable

UTP

CAT5

4 pairs

to

send

the

control voltages

to

the rotors.

With

2 Power connectors and one DB15 male connector.

( You can avoid the multipin connectors, connecting the cable directly to the Rotors terminals 1,2,3).

- 1

Driver

with

free

Download

here

to be installed in

the

PC

following the instructions.

The program

BB_TRACKER

is

a

Driver

that runs under

Windows

and

is

inserted

in

the

Orbitron

configuration.

The

driver

receives data from

Orbitron

and sends

them to

the

PCB

equipped with

a

microcontroller

that

commands

the controllers

of the rotors

for

the azimuths

and

elevations.

The rotors and

the

controllers

have

synchronous motors.

For

azimuths,

we

made

a

printed circuit board

with

60

position green

LEDs in

circumference

at 6

degrees

angles

(Sectors

of

6º)

which are sufficient

to maintain

tracking

of

satellite

antennas

with

lobes

of

+ - 3

degrees

@

-3

dB.

The

elevation

PCB

have

15

LEDs

corresponding to

15

sectors of 6º.

In

the

rotating disk

of

the

controllers

we

installed

a

photodiode

which

detects

the

LED

light

stopping

in the center

of the respective

sector.

The

software

always calculates

the

shortest route

around

360 degrees

and walk

accordingly.

The program

also warns that

will carry out

a reset

of turns

for

compensation,

in order to avoid

winding

the cables

around the

support

of the antennas.

BLOCK DIAGRAM

![]()

1 - Turns on the LEDs of the azimuth and elevation where the rotors should move to.

2 - Connects the current supply of the drivers on both rotors through the relays RL1 and RL2

3 - Actuates the relay RL3 and RL4 to define the direction of the rotors movement : In azimuths if it is CW or CCW. In the elevation if it is 90 ° upwards (UP) or down to 0 ° (down).

When the photo diode reaches the lighting LED, it sends an information to the microcontroller to disable all the devices previously activated.

The relays RL5 and RL6 are intended to cut off the current from the rotors keeping the controllers working to synchronize the system.

The software

acquires

the

data

automatically

from

the

Orbitron

processing them

as follows:

- Extracts

the

data

through the protocol

DDE (Dynamic

Data

Exchage)

in a

Satscape

string

format.

- Inserts

data

in

the

reading windows

for viewing.

- Processes

the

data from

windows

comparing

the values with

the

ranges

of

sectors

and sends a

related

signal

to the angle-LED

where

the Micro

should send the

rotor,

the LED

lighting

sector

- The software

also compares

current data

with

the previous one to

know

which way

is

shorter

to

move the

rotor (CW

or CCW).

It

also calculates

the

number of

sectors

CW and

CCW to

where the rotor

will be

sent. It calculates the travelling of the azimuth rotor to

notice

to do

a

RESET

and

avoid cable turns around the mast.

-

Even after

turning off the

PC,

the data

of

the

Last

Position

of the antenna

is

stored.

-

In the case

of the

Last

Antenna Position

values

indicated by

the

program does not

match the

actual orientation

of the antenna,

it is because something

has been forced.

To fix

it,

just

press

the knob

SYNC

(when in orange)

that will

synchronize

the

system

- Button-Start / Stop to trigger the automatic tracking from Orbitron data.

- Start-button to activate the manual system with the windows where are inserted the intended azimuths and elevations.

- Button-SYNC to synchronize the actual orientation of the rotors with the controllers.

System

It uses a Software Driver running

with Orbitron, a microcontroller in a PCB accessed by the PC USB port,

which

controls the modified Controller Box.

The Software Driver receives data from Orbitron processes it and sends the commands to the microcontroller which, in turn, sends data control to the Rotor Controller.

HOW

IT WORKS

The concept is to

replace the

original controller button with an hardware which

simulates the manual operation.

This is done

replacing the

rotable

controller

dish

with a PCB with

leds which represents the

centre of

angle

sectors.

In the white

plastic rotable dish we put a photodiode which

detects the activated led and stops.

We divided one complete turn of 360º in 60 sectors of 6º each for the azimuths and 90º 15 sectors for elevations.

The reason for the sectors is to permit an antenna pause between +- 3º of satellite passage inside a 6º arc.

For example: the sector 5 will be between 24º and 30º and the antenna will be

pointed

in the midle

27º

during the passage.

As soon as the satélite azimuth is out of the sector, the software driver sends a command to the microcontroller to activate the next sector led and the (white plastic) dish of the controller runs 6º and stops.

SOFTWARE DRIVER FUNCTIONS FOR THE ORBITRON

The driver

catches the data from Orbitron with the DDE protocol in the Automatic mode or catches

data from the windows in the Manual mode.

The movement of the azimuth rotor is free from any mechanical limitation so, it will be possible to turn more than 360º around without being interrupted in the middle of a satellite pass .

To prevent

that automatic resets occurs during the satellite passage, the RESET button

will become

In the

Manual operation, the Azimuth and Elevation are inserted in the windows to

command the antenna position.

The SINC button is to synchronize the physical antenna position with the system data. It can occur with heavy wind or data loss and the software position do not corresponds to the physical antenna position.

HOW WE DEVELOP THE PROTOTYPE

The only care is to balance the antenna placing it to the rotor in its center of gravity

HOW TO MODIFY THE ROTOR CONTROLLERS

Contacts removed Aligning the PCB

-

Marking holes for the leds Drilling of small holes

In the final stage, holes will be precisely placed by a PCB software design and professional PCB manufacturer.( SEE IT HERE )

Layout

Placing the 60 LEDs on the disk of the azimuths AND 15 LEDs on the disk of the elevations. Phototransistor and shrink sleeve

Sleeve placed on phototransistor Pin where to put the phototransistor

Phototransistor placed . Screws were removed because are not necessary. The sleeve stands the fototransistor. Photodiode will run down and around the leds.

15 Elevation diodes placed. ( Note:Each diode representes the center of a sector of 6º ) Flat cable 16 connected to the Microcontroller PCB

For Azimuth we have 60 sectors ( 60 leds) divided in four quadrants of 15 sectors. Four flat cable 16 wil connect diodes to the microcontroller PCB

Note : These two PCBs are a prototype design and will be replaced by the new comercial PCBs shown above.

Assembled system to put in to a metalic box

All Relais, and wires, will be placed in a single PCB after this prototype

HOW TO MODIFY THE AZIMUTH ROTOR

Remove the blocking pins in the gear

Exterior microswitch installed in the Azimuthe Rotor. The cam (ledge) switches on the stop at zero. The Brown and Brown/White wires belongs to the UTP CAT5 cable.

Wiring the UTP cable to the rotors. In both rotors, connections are the same.

Connectors used and glued to the rotors to allow easy transportation. Soldering the female pins of the connestors

Note : These numbers are the numbers of the Pin connectors and the number of the DB15 Pin also. They are note the numbers of the Rotor terminal.

As

seen in the picture before;:

The Blue cable will connect to the pin 2

The Orange

to the pin 1

The Green to the pin 3 .

The Brown and White/brown wires will connect to the microswitch opened contacts in both rotors.

Soldering the two UTP cables (Azim.and Elev.) to the DB15 male connector Soldering the internal wires to the female of DB15 connector

Back view of the prototype Box.

Top view

BB_TRACKER, Antennas, Rotors, Tripod, Mast and Radios ready for a Satellite Field Day...